By Paul Fooks

Special to Ottawa Construction News

Fall protection equipment used in the workplace must be made to a CSA standard that will ensure an adequate safety factor if the equipment is loaded during an accidental fall. The main considerations I have are that the equipment may be rated but, if a worker does not use it in its intended manner, the equipment can fail.

The topic that I will be introducing is the prevention of connectors being used in a dangerous way. One simple useful connector is the carabiner. When I introduce the carabiner to students during Working at Heights Training, I always start with the carabiner’s strengths. The two main strengths are the carabiner is easy to open and can connect almost anything together. I will back that up with the biggest weakness is the carabiner is easy to open and can connect almost anything together.

This is not an editing misstep — it is a fact. The biggest strength is the biggest weakness. Carabiners use a double lock that requires a physical rotation of the locking cylinder and the gate needs to be pushed inwards to overcome spring pressure. The problem that may occur is the gate may be forced against a firm object that rotates the cylinder and pressure opens the gate. I demonstrate this by pressing the carabiner against my palm at an angle. See Figure 1.

The solution is to ensure no objects are in the vicinity of the connection that can create this action.

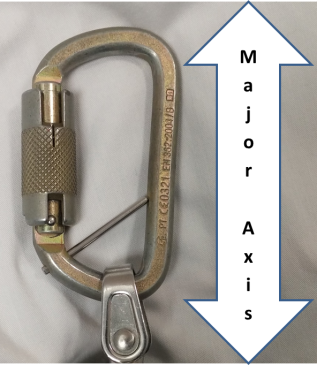

Another risk with the carabiner is called gate loading. This is where the load for the system is being pressed on the minor axis of the carabiner. If the carabiner is gate loaded and there is a twist in the system, the force will accelerate against the gate and potentially cause a failure. In most cases the gate being opened or the gate being loaded can reduce the strength of the carabiner by 50 to 60 per cent or more. The prevention of gate loading can be significantly reduced by installing the carabiner with the gate towards the ground and installing the locking pins to load the carabiner on the major axis. See Figure 2.

(figure 2)

Other risks to the carabiner include side loading against an object, cross loading or triaxle (three-way) loading and dropping them without taking them out of service. Dropping a carabiner is a study in itself I cannot discuss in a short article but I encourage carabiner users to investigate this further and follow the manufacturer’s manual for the equipment.

The second connector is the double locking snap hook which also has performance limitations as well. Lanyards equipped with double locking snap hooks can also be gate loaded.

Two circumstances are prevalent with the use of a carabiner for fall protection. The first circumstance is when the carabiner is installed with the gate above the hook and the anchor ring is touching on the gate. A twist in the system can create the potential to burst open the gate. The solution can also be to install the gate towards the ground which leaves the solid portion of the hook suspended from the ring.

The second circumstance is larger scaffold hooks being used on the floor where the connector can become twisted placing the gate against the anchor ring. I only use the scaffold hook in a hung or suspended connection where the thin part of the hook or the gate cannot become loaded. These recommendations are reinforced in the owner’s manuals of equipment that workers use for fall protection.

Read the manual, follow the safety rules and make a safe connection.

Paul Fooks is head trainer for Labor Tek Safety Training Inc. For more information, visit www.labortek.com or phone (613) 741-1128.